Four elements of gear motor selection

Feb 21,2025

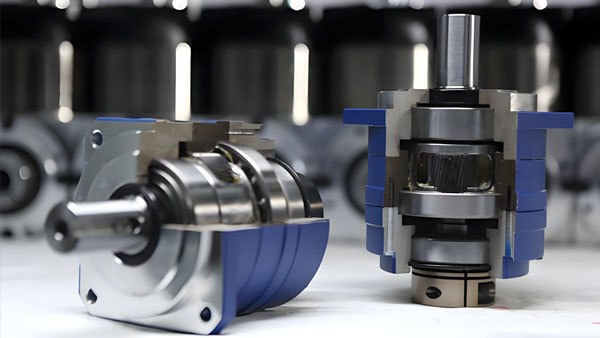

The four elements of gearmotor selection Gearmotors are components of gearboxes and motors. Such components can also be called gearbox motors or geared motors, which are usually integrated and assembled by professional gearbox manufacturers and supplied in sets.

Gearmotors are widely used and are indispensable power transmission equipment for automated machinery and equipment, especially packaging machinery, printing machinery, corrugated machinery, color box machinery, conveying machinery, food machinery, three-dimensional parking equipment, automatic storage, three-dimensional warehouses, chemical, textile, dyeing and finishing equipment. Micro gear motors are also widely used in electronic locks, optical equipment, precision instruments, financial equipment and other fields.

Gear Motor

The selection of geared motors should be based on the principles of practicality, economy, and correctly selecting its power, type and model according to the production requirements in order to ensure the smooth progress of production.

1、Economic choice

Generally speaking, imported products are much more expensive than domestic ones, and those from Hong Kong, Macao and Taiwan are more expensive than those from MAINLAND China. (The specific situation depends on the specific needs of enterprises). Nowadays, most of the manufacturers in the gearmotor market, whether imported or domestic, have their own naming standards, so look for a sample of the gearmotor and choose the model according to the sample.

2、Type selection

There are two types of gear motors: cage and wire-wound. Cage-type gear motor structure is simple, easy to maintain, inexpensive, but poor starting performance, can be used for no-load or light-load starting production machinery; wire-wound gear motor starting torque is large, starting current is small, but the structure is complex, start-up maintenance trouble. Can only be used for lifting equipment and other occasions that require large starting torque, can also be used for mechanical equipment that requires proper speed regulation.

3、Choice of power

The power selection of the gear motor is determined by the production machinery, that is, the power required by the load. The required motor power of the gear motor is as follows: motor power = torque 9550 motor power input revolutions speed ratio use coefficient.

4, The choice of speed

Gear motor speed close to the synchronous speed, while the magnetic field speed using the pole logarithm P classification, there is no speed between the two gears. Gear motor speed selection principle is as close as possible to the speed of the production machinery, thus simplifying the rotating device.

PREVIOUS:

Contact Us

E-mail :

106549183@qq.com

Tel:

+86 15166666358

Address:

No.88 Keyun Road, Chengyang District, Qingdao, Shandong Province, China