How to install a planetary gearbox correctly

Feb 21,2025

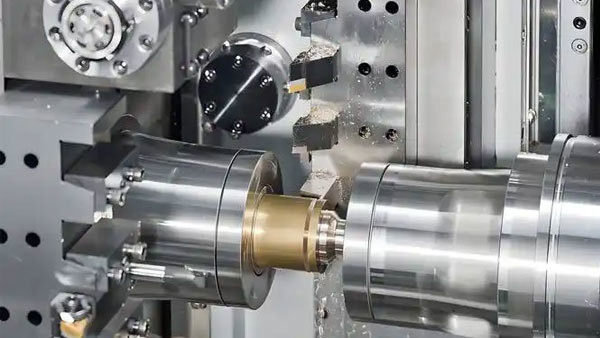

In the gearbox industry, gearboxes are widely used in servo, stepper and DC drive systems because of their quietness, high precision, high rigidity, high torque and no grease leakage. Its function is to reduce the speed, increase the torque and reduce the load/motor inertia ratio under the premise of ensuring transmission. In the past few years, some users have suffered losses due to the breakage of the output shaft of the reducer caused by human factors such as illegal installation when using the reducer, so that the enterprise suffered losses. Therefore, in order to help users use the reducer well, the causes of broken shafts of the reducer and drive motor are analyzed, and how to install the planetary reducer correctly is described in detail.

Some users break the output shaft of the drive motor after the equipment has been running for a few months. Why would the gearhead twist off the output shaft of the drive motor? For this reason, we examined the cross-section of the drive motor's output shaft and found it to be almost identical to the cross-section of the gearhead's output shaft. The outer ring of the cross-section was brighter, while the color of the cross-section towards the shaft was darker and broke at the shaft! This is a good indication that the main reason for the drive motor output shaft breaking is that the motor and gearhead are not concentric when assembled.

When the concentricity of the assembly between the motor and the gearhead is well ensured, the motor output bearing only receives rotational force and runs smoothly. Then, when it is not concentric, the output shaft will be subjected to radial force from the input of the gearhead. The long-term effect of this radial force will cause the motor output shaft to bend, and the direction of bending will change with the rotation of the output shaft. For every rotation of the output shaft, the direction of the transverse force changes by 360 degrees. If the concentricity error is large, the radial force will cause the temperature of the motor output shaft to rise and its metal structure to be continually damaged. The radial force will exceed the radial force that the motor output shaft can withstand, and the drive motor output shaft will break. When the concentricity error is large, the output shaft of the drive motor breaks, and at the same time, the input end of the gearhead will also be subjected to radial force from the motor. If the radial force exceeds the large radial load that both can withstand at the same time, the input end of the gearhead will be deformed or even broken. Therefore, it is very important to ensure concentricity during assembly!

Intuitively, if the motor shaft and the input end of the reducer are concentric, the fit between the motor and the reducer will be very tight, and the contact surfaces between the two will be tightly connected, whereas if they are not concentric when assembled, there will be gaps in the contact surfaces between the two.

Similarly, the output shaft of a gearhead breaks or bends for the same reason that the shaft of a drive motor breaks. However, the output of a gearhead is the product of the output of the drive motor and the reduction ratio. The output shaft of a gearhead is more likely to break than that of a motor. Therefore, users should also take great care to ensure the concentricity of the output components of the gearhead when using it. Secondary speed reducer outputs too small to cause shaft breakage

In addition to the poor concentricity of the reducer output leading to reducer shaft breakage, if the reducer output shaft breaks, the reasons are as follows.

Selection error leads to insufficient reducer output. Some users mistakenly think that only the rated output torque of the selected reducer can meet the working requirements when selecting the type, which is actually not the case. The rated output torque of the matched motor multiplied by the reduction ratio will in principle be less than the rated output torque of the similar reducer provided in the product samples; secondly, the overload capacity of its drive motor and the actual required larger working torque should be considered at the same time. Theoretically, the larger working torque required by the user. It must be less than twice the rated output torque of the reducer. Especially in some applications, this guideline must be strictly adhered to, not only to protect the reducer, but also to avoid the output shaft of the reducer being twisted. This is mainly because if there is a problem with the installation of the equipment and the output shaft of the gearhead and its load are jammed, the overload capacity of the drive motor will still allow it to increase its output, which may result in the output bearings of the gearhead being subjected to more than twice the rated output torque, twisting the output shaft of the gearhead.

Second, during acceleration and deceleration, if the instantaneous torque multiplied by the output shaft of the gearhead is more than twice its rated output torque and the acceleration and deceleration are too frequent, the gearhead will break its shaft. Considering that this situation is relatively rare, it will not be described further here.

The correct installation, use and maintenance of the speed reducer is an important part to ensure the normal operation of mechanical equipment. Therefore, when installing the planetary reducer, please follow the following installation and use related matters strictly and assemble and use it carefully.

The step is to confirm whether the motor and reducer are intact before installation, and strictly check whether the dimensions of the parts connected to the motor and reducer match. The following are the dimensions and matching tolerances of the motor positioning cam, input shaft, and reducer groove. In the second step, loosen the screws on the dust holes on the outside of the reducer flange, adjust the snap ring so that the side holes are aligned with the dust holes, and insert the hexagonal socket to tighten it. After that, take away the motor shaft key. The third step is the natural connection between the motor and the gearhead. When connecting, the concentricity of the output shaft of the gearhead and the input shaft of the motor must be the same, and the outer flanges of the gearhead and the motor must be parallel. Due to the inconsistent concentricity, it will cause the motor shaft to break or the gears of the gearhead to wear out. In addition, it is strictly prohibited to strike with hammers, etc. during installation. This is to prevent excessive axial or radial forces from damaging the bearings or gears. Be sure to tighten the mounting bolts before tightening the fastening bolts. Before installation, wipe the motor input shaft, positioning tabs and reducer connections with gasoline or zinc-sodium water to remove the rust preventive oil. The purpose of this is to ensure tightness of the connection and flexibility of operation, and to prevent wear. Before connecting the motor to the gearhead, make the keyway of the motor shaft perpendicular to the tightening bolt. To ensure uniform force, tighten any diagonal mounting bolts first, but do not tighten them, then tighten the other two diagonal mounting bolts, and then tighten the four mounting bolts one by one. z Finally, tighten the tightening bolts. All tightening bolts should be fixed and checked with a torque wrench according to the marked fixing torque data.

The correct installation between the gearhead and mechanical equipment is similar to the correct installation between the gearhead and the drive motor. The key is to ensure that the concentricity of the output shaft of the speed reducer is the same as the concentricity of the driven part of the shaft.

With the continuous development of industry in various countries, the role of reducer in the transmission field is becoming more and more obvious. We hope that the speed reducer will bring you more convenience and benefits in the future!

PREVIOUS:

Contact Us

E-mail :

106549183@qq.com

Tel:

+86 15166666358

Address:

No.88 Keyun Road, Chengyang District, Qingdao, Shandong Province, China