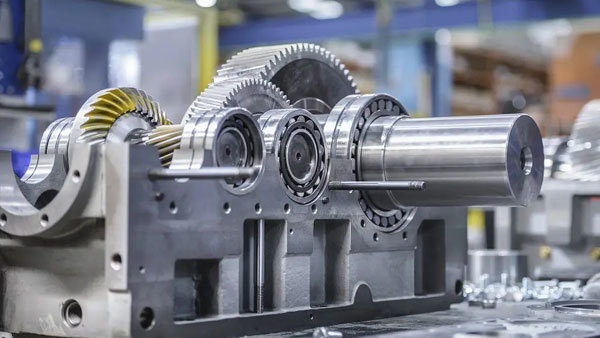

Heat treatment of gears for planetary gear drives

Feb 21,2025

The weight of a planetary gearing unit is, in general, directly proportional to the weight of the gear, which is strongly related to its material and heat treatment hardness. For example, under the same power, the weight of carburized quenched gears will be about 1/3 of the weight of tempered gears. So for the structural characteristics of the planetary gear reducer and the load nature of the gear, hardened gears should be widely used. There are many heat treatment methods to obtain hardened gears, such as surface quenching, overall quenching, carburizing quenching, nitriding, etc., which should be considered and selected according to the characteristics of the planetary gear reducer.

1、Surface quenching

Common surface hardening methods are high frequency quenching (for small size gears) and flame quenching (for large size gears) two. Surface hardening of the hardened layer including the bottom of the root of the tooth, its effect is good. Surface quenching commonly used materials for carbon mass fraction of about 0.35% ~ 0.5% of the steel, tooth hardness up to 45 ~ 55HRC.

2, carburizing quenching

Carburized quenched gear has a relatively large bearing capacity, but must be used in the finishing process (grinding teeth) to heat treatment deformation to ensure accuracy.

Carburizing quenched gears commonly used before carburizing carbon mass fraction of 0.2% ~ 0.3% of the alloy steel, its tooth hardness is often in the range of 58 ~ 62HRC. If lower than 57HRC, the tooth surface strength decreased significantly, higher than 62HRC is brittle increase. The hardness of the heart of the gear tooth is generally 310~330HBW. Carburizing quenching gear hardness, from the surface of the gear teeth to the deep layer should be gradually reduced, while the depth of carburization is specified as the surface to the deep layer should be gradually reduced, while the depth of carburization is specified as the surface to the depth of hardness 52.5HRC.

Carburizing quenching in the bending fatigue strength of gear teeth in addition to the role of the hardness of the heart has improved, but also lies in the surface of the residual compressive stress, which can make the gear teeth tensile stress zone stress reduction. Therefore, when grinding teeth can not grind the root part of the tooth, hobbing to use the amount of hob to stay grinding.

3、Nitriding

The use of nitriding can ensure that the gear teeth in the deformation of small conditions to achieve high tooth hardness and sex, heat treatment can no longer be carried out after the finishing process, improve the load-bearing capacity. This is not easy to grind the teeth of the internal gear, has the significance.

4, want to mesh gear hardness combination

When the large and small gears are soft tooth surface, the tooth surface hardness of the small gear should be higher than the large gear. And when both wheels are hard tooth surface and high hardness, take the same hardness of both wheels.

PREVIOUS:

Contact Us

E-mail :

106549183@qq.com

Tel:

+86 15166666358

Address:

No.88 Keyun Road, Chengyang District, Qingdao, Shandong Province, China